-

Automatic pen rod screen pri...

[2018/4/20 10:40:47]Automatic pen rod screen printing machine (new upgraded feeding system) APS-150B...

-

Automatic UV Silk Screen Pri...

[2018/3/21 22:49:05]Automatic UV Silk Screen Printing Machine with Optical Registration System model SCUV-16C...

-

automatic Screen Pad Printin...

[2018/3/16 15:01:08]automatic Screen Pad Printing machine for caps sidewall and top (SCUV-16B) Automatic Screen Pad Printer for Caps sidewall and top 1: Max.Print Size...

-

Customer from Poland come to...

[2017/9/18 14:54:40]Customer from Poland come to check and his automatic silk screen printing machine on lipstick and polish glass nail bottles...

-

The Agent from Sri Lanka vis...

[2017/7/29 12:20:00]The Agent from Sri Lanka visits Our Factory...

Add: Building 2,No.26th, HuiHeTianDi Industrial Zone,JiaHeWangGang, Guangzhou, China.

Tel.: 020-37937186

Fax: 020-37937189

Email: sales@printermaker.com

Web: https://www.printermaker.com

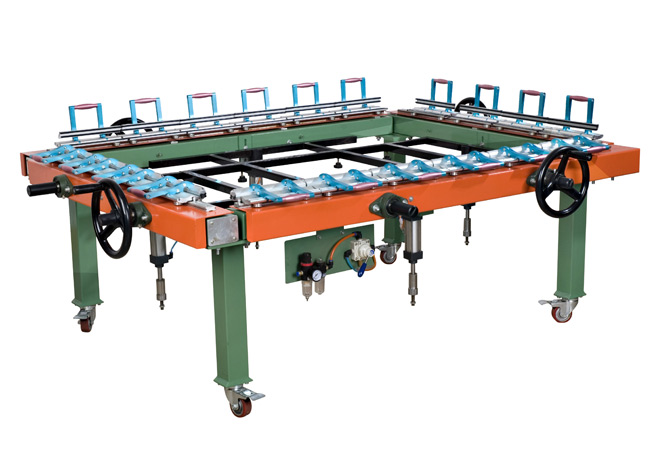

Screen Stretching Machine

|

Screen Stretching Machine

The first step is tightened silk onto Screen frame made by Aluminium frame, Wooden Frame, Steel frame with Tighten silk machine; Air-controling to hold Metal shelf ensure contact compactly with silk surface ; Hand-wheel operated to make precision tension . Many frames to be tightened meantime ensure same silk tension and correct overprint.

Price Terms:FOB GuangZhou

Payment Terms:T/T. LC

Packing:Wooden case

Lead Time:Within 3 days

Standards Certificate:ISO9001-2000

Colour Painted:GREEN

Specifications:

M-1200LW: (Price at 1600USD)

1.Max tighten area:1000×1200mm.

2.Dimension:1200×1400×800mm.

3.Net weight:85kg.

4.Max silk tension:30N/CM.

M-1600LW: (Price at 1980USD)

1.Max tighten area:1200×1600mm.

2.Dimension:1300×1700×800mm.

3.Gross weight:270kg.

4.Max silk tension:30N/CM.

5. Packing Size:1800*1100*650mm

M-1500LW: (Price at 2,200USD)

1.Max tighten area:1500×1500mm.

2.Dimension:1600×1700×800mm.

3.Gross weight:270kg.

4.Max silk tension:30N/CM.

5. Packing Size:1800*1100*650mm

M-2200LW: (Price at 2500USD)

1.Max tighten area:1700×2200mm.

2.Dimension:1800×2300×800mm.

3.Net weight:400kg.

4.Max silk tension:30N/CM.

M-2300LW: (Price at 3000USD)

1.Max tighten area:2300×2300mm.

2.Dimension:2450×2450×800mm.

3.Net weight:600kg.

4.Max silk tension:30N/CM.

Advantages:

1. High strength frame made by aluminium alloy.

2. Easy to adjust tighten silk area by pushing and pulling leader of machine.

3. More uniformity tension to keep printing quality by air to raise up silk.

4. Hand draught silk so that get more propriety tension .

Ship Date:

by sea:

within 30 days after receive T/T.

Testing:5-7 bar compress air.

Screen Stretching Machine Manufacturer search on: Google, Yahoo, Msn

China

China Deutsch

Deutsch Espanol

Espanol Francies

Francies Italino

Italino Portgues

Portgues Japan

Japan Korea

Korea Arabia

Arabia Russia

Russia Indonesia

Indonesia Vietnam

Vietnam