-

Automatic pen rod screen pri...

[2018/4/20 10:40:47]Automatic pen rod screen printing machine (new upgraded feeding system) APS-150B...

-

Automatic UV Silk Screen Pri...

[2018/3/21 22:49:05]Automatic UV Silk Screen Printing Machine with Optical Registration System model SCUV-16C...

-

automatic Screen Pad Printin...

[2018/3/16 15:01:08]automatic Screen Pad Printing machine for caps sidewall and top (SCUV-16B) Automatic Screen Pad Printer for Caps sidewall and top 1: Max.Print Size...

-

Customer from Poland come to...

[2017/9/18 14:54:40]Customer from Poland come to check and his automatic silk screen printing machine on lipstick and polish glass nail bottles...

-

The Agent from Sri Lanka vis...

[2017/7/29 12:20:00]The Agent from Sri Lanka visits Our Factory...

Add: Building 2,No.26th, HuiHeTianDi Industrial Zone,JiaHeWangGang, Guangzhou, China.

Tel.: 020-37937186

Fax: 020-37937189

Email: sales@printermaker.com

Web: https://www.printermaker.com

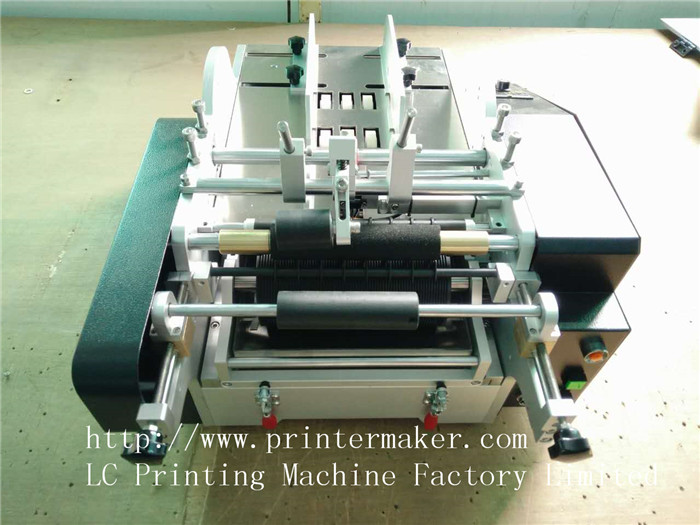

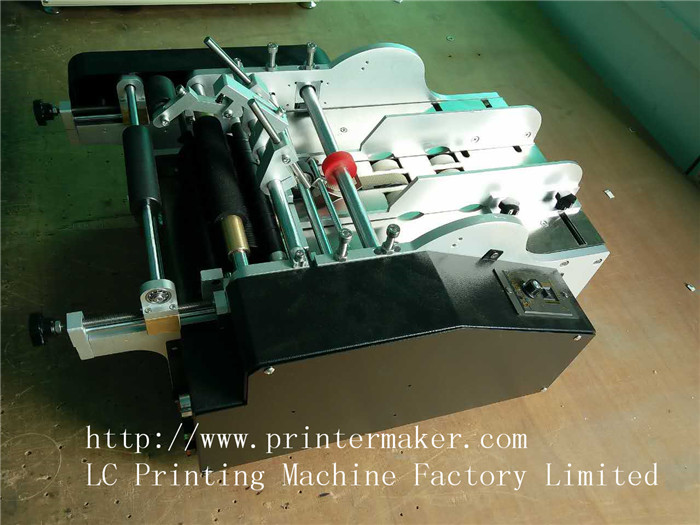

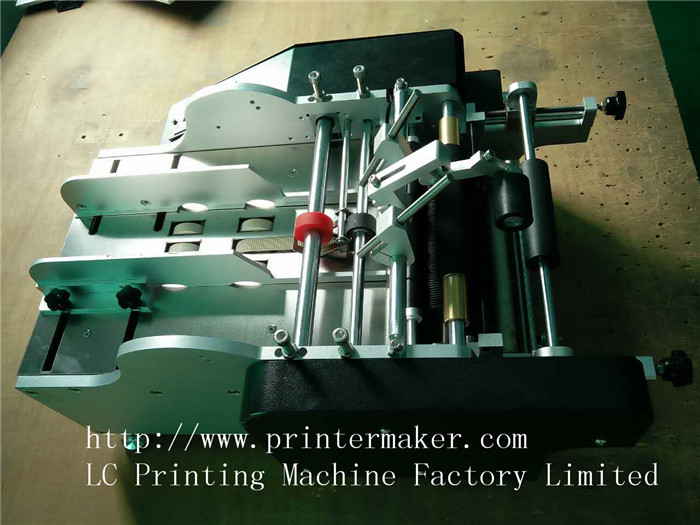

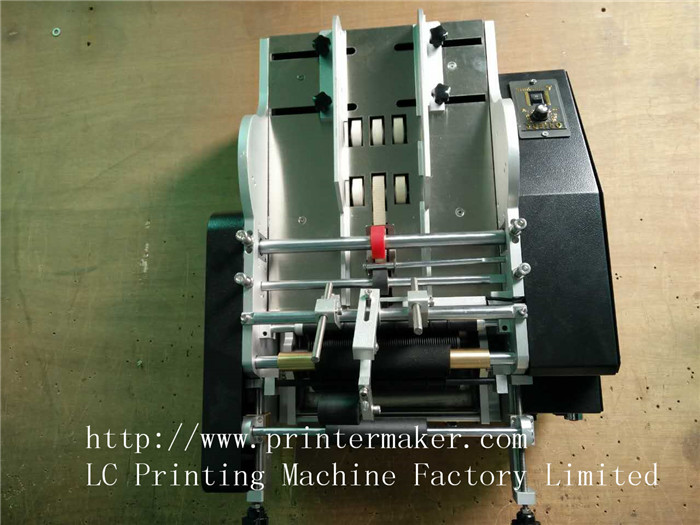

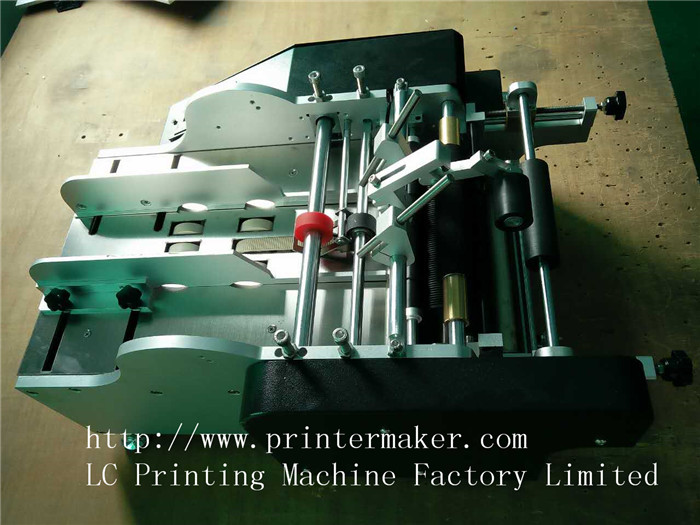

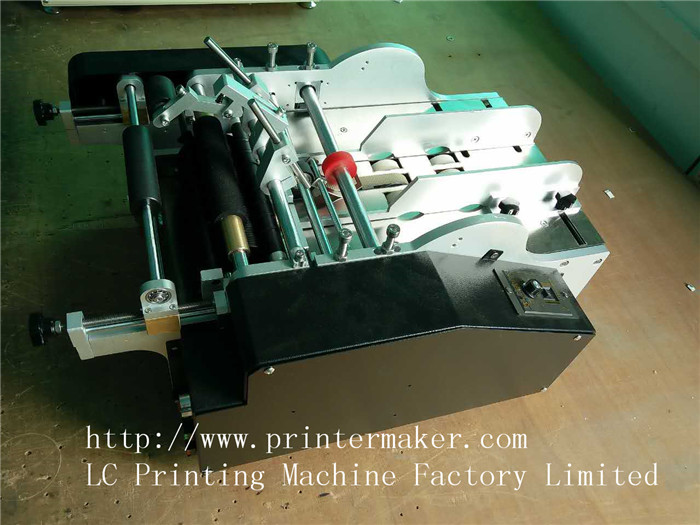

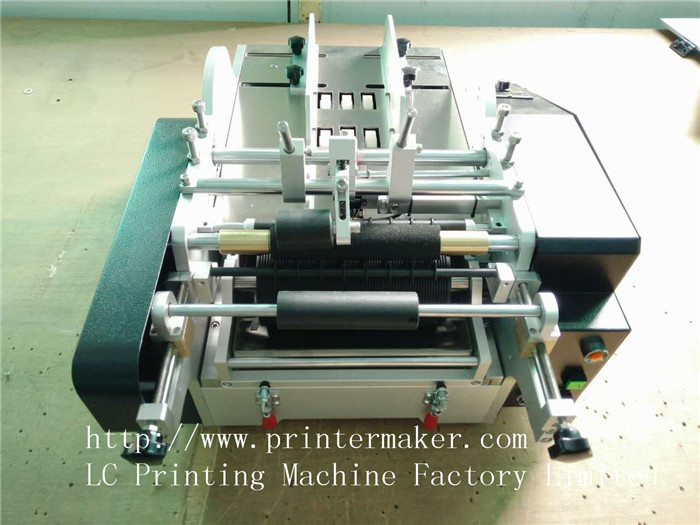

Paste Labeling Machine

|

Paste Labeling Machine,Glue Labeling Machine

Application

This machine is applied to label the label paper on various cylinder bottles and containers.

This machine is widely used in pharmacy, foodstuff, beverage, cosmetic and chemical etc

industries. Such as can, beer and various glass bottles etc.

Applied label: label paper ( not adhesive sticker label)

Applied product: cylinder bottle, cylinder container.

Principle of work: When the sensor detects the signal of product, A piece of label paper will be sent, and then coated paste

and labeling can be completed on the products automatically. Then the label units return to in situ, wait next signal.

Operating progress

put product automatic detect product send label paper +coated paste + labeling (automatically) remove the finished product

Feature

1. Adopt original labeling technology to ensure the stability of labeling and positioning accuracy. No air bubble, no wrinkle, and raise the additional value of products.

2. The frame and shell adopt stainless steel and high class aluminium alloy anodic treatment, the useful time is long.

3. Adopt famous factory step motor to ensure high load and long period operation.

4. With PLC, clutch and electric eye control, ensure the labeling accuracy, the operation is simple and convenient, the function is stable.

5. Open frame, adjust the label paper of different sizes and change parts are all convenient.

6. Disconnect - type design for the glue-plate, frictioning knife and glue-wheel, so the cleaning is very easy.

7. The efficiency is about three to four times than manual operation, reducing labor cost, and management cost.

8. With the functions of autocorrection and automatic detection when no label.

9. With the functions of fault alarm and production counting.

Specification:

1.Label width: 40-200mm

2.Label length:80-380mm

3.Products Diameter:

Diameter : φ30mm-φ120mm

Height : 30mm-230mm

4.Max Labeling speed: 35pcs /min

5.Accuracy of labeling:±1mm

6.Power: 220V/110V 50/60Hz 80W

7.Machine Net Weihgt : 40KG, Gross Weight:54KG

8.Machine Dimension: 630mm x 430mm x 330 mm

9.Packing Size:860*670*690MM

Paste Labeling Machine Manufacturer search on: Google, Yahoo, Msn

China

China Deutsch

Deutsch Espanol

Espanol Francies

Francies Italino

Italino Portgues

Portgues Japan

Japan Korea

Korea Arabia

Arabia Russia

Russia Indonesia

Indonesia Vietnam

Vietnam