-

Automatic pen rod screen pri...

[2018/4/20 10:40:47]Automatic pen rod screen printing machine (new upgraded feeding system) APS-150B...

-

Automatic UV Silk Screen Pri...

[2018/3/21 22:49:05]Automatic UV Silk Screen Printing Machine with Optical Registration System model SCUV-16C...

-

automatic Screen Pad Printin...

[2018/3/16 15:01:08]automatic Screen Pad Printing machine for caps sidewall and top (SCUV-16B) Automatic Screen Pad Printer for Caps sidewall and top 1: Max.Print Size...

-

Customer from Poland come to...

[2017/9/18 14:54:40]Customer from Poland come to check and his automatic silk screen printing machine on lipstick and polish glass nail bottles...

-

The Agent from Sri Lanka vis...

[2017/7/29 12:20:00]The Agent from Sri Lanka visits Our Factory...

Add: Building 2,No.26th, HuiHeTianDi Industrial Zone,JiaHeWangGang, Guangzhou, China.

Tel.: 020-37937186

Fax: 020-37937189

Email: sales@printermaker.com

Web: https://www.printermaker.com

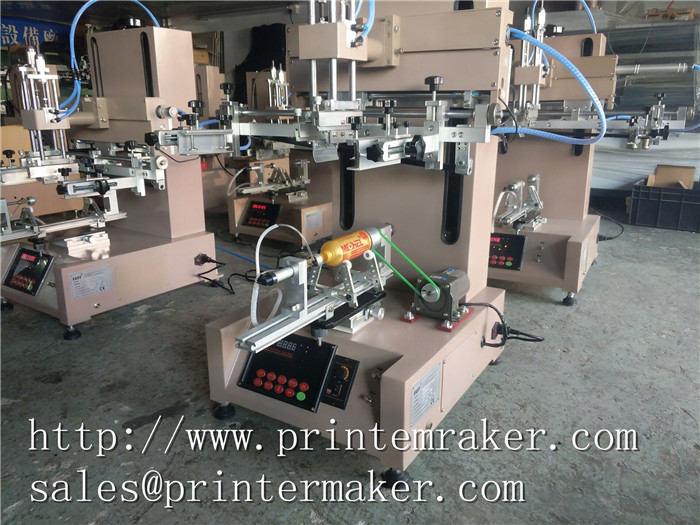

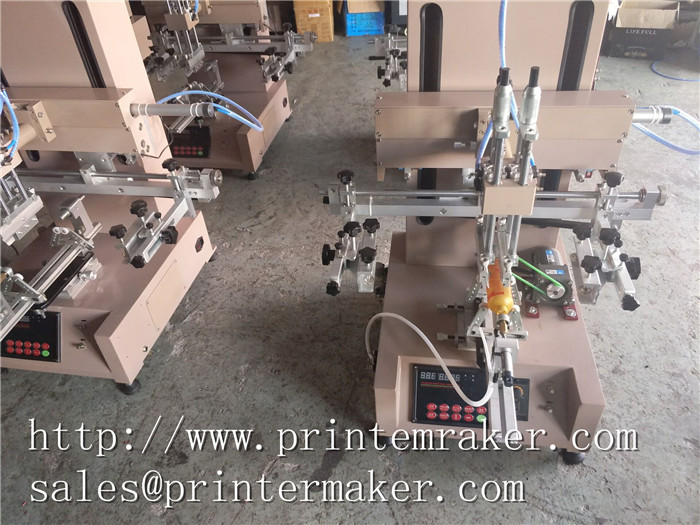

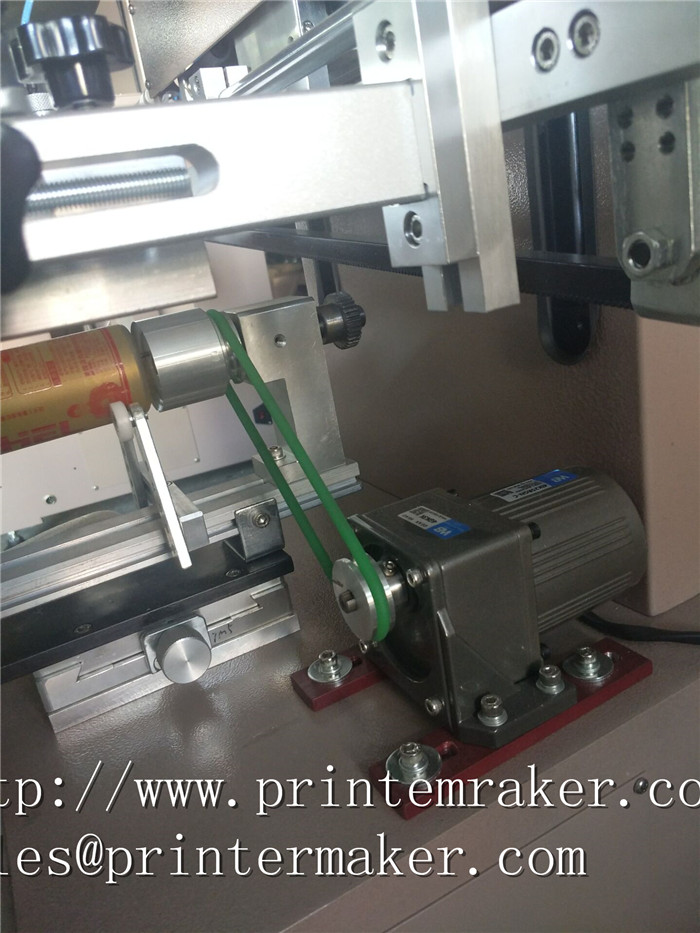

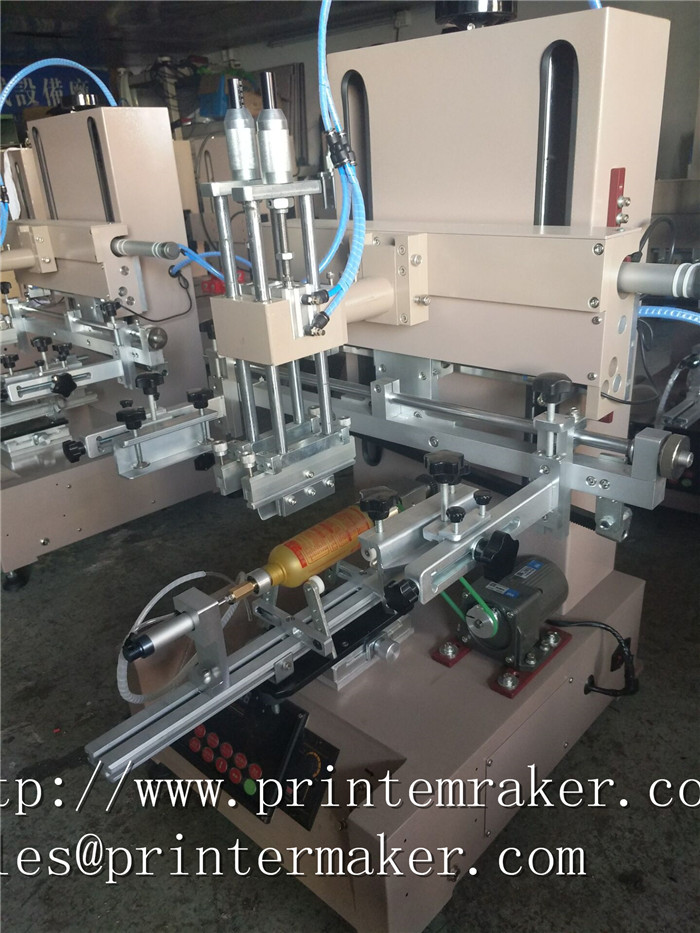

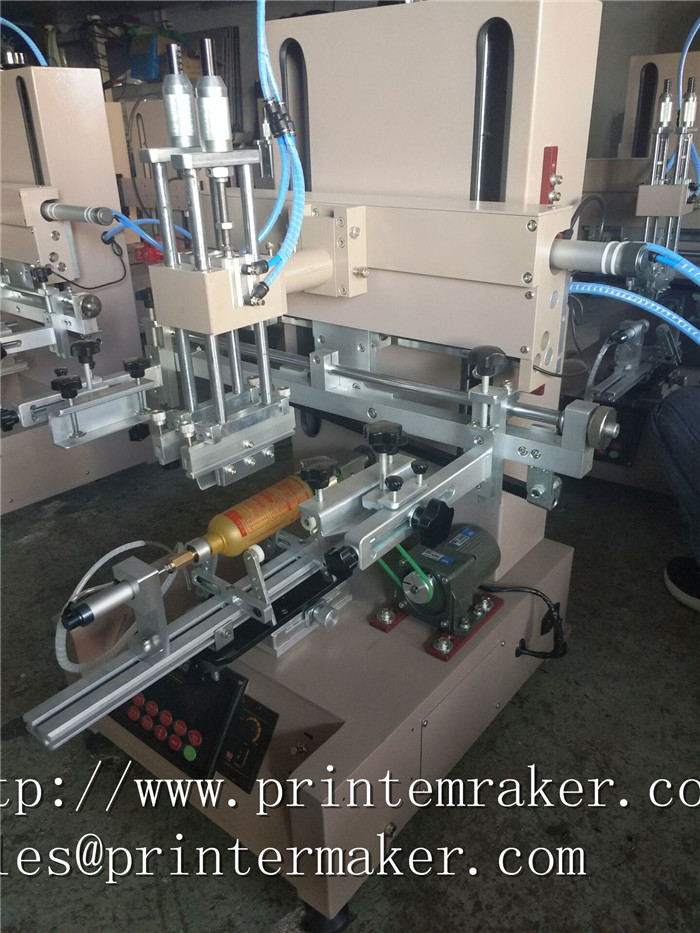

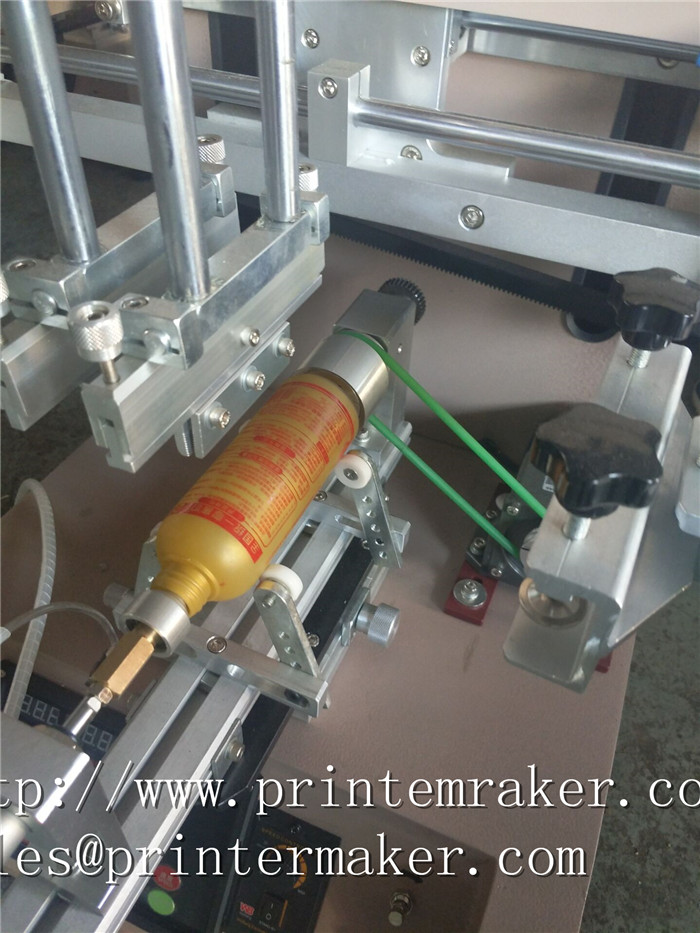

Mini Bottle Screen Printing Machine

|

Mini Bottle Screen Printing Machine

Parameter:

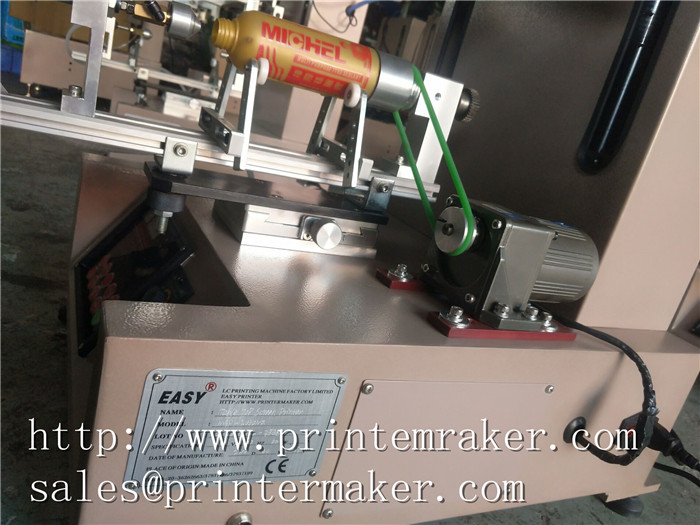

Mode:MSP-2030UQ

Print Area: 300mm(the length of circumference or cambered surface)*200mm (width)

The maxium printing diameter: 95mm

Printable diameter: 5~150mm

Print Speed:1200pcs/hour

Power:110V/200V 50W

Machine Size:80*90*90CM

Packing size: 104*98*92CM(L*W*H)

Net Weight:125KG

Gross Weight: 175KG

Volume weight:180KG

Function introduction:

The Mini cylindrical screen printing machine is adopted imported (Taiwan) pneumatic parts with quick speed, stable quanlity, lower noise, precise over-printing, 350mm stroke. It is suitable for printing the surface of round products with 100mm diameter, such as cosmetic products, chemical container, food packing cans and other related cylindrical products. As the volume is small, the application field is wide, the price is favourable, the machine is the most popular machine in the market. It is the best favourable machine.

Features:

1. SCM IC coordinate light touching panel to complile action programming

2. Auto 4-digit counter built-in, counting printing quantity

3. Airframe adopts coin alloy,and metal coating surface

4. distyle vertical constructure, high precision, steady operation

5. the transeversa stroke can be adjusted, spacing by Taiwan electronic switch

6. the angle of scraper and ink covering blades can be adjusted randomly

7. installing scraper constant pressure equipment to make sure pressure is steady when printing

8. you can regulate work-table back and forth or right and left, and then fastening it

9. you can regulate screen frame back and forth, right and left or level orientatio

10. vacuum stainless steel worktable, it can absorb kinds of film products

11. installing CEC oil buffer on up and down, left and righ to avoid printing shock

12. The machine is running fastly, steably and lower noise.

13. Action model option: fully automatic | semi-automatic | manual

14. Start-up method:panel | foot switches

15. scraper pressure controller:by pressure regulating Valve

16. vertical driving style: pneumatic

17. transeversa driving style: pneumatic

Mini Bottle Screen Printing Machine Manufacturer search on: Google, Yahoo, Msn

China

China Deutsch

Deutsch Espanol

Espanol Francies

Francies Italino

Italino Portgues

Portgues Japan

Japan Korea

Korea Arabia

Arabia Russia

Russia Indonesia

Indonesia Vietnam

Vietnam